Does the BIKEDRIVE AIR S e-bike motor pass the toughest tests? – Part 2

Details

After mastering the basics, the ultimate stress test begins for the maxon e-bike drive: vibrations, changing loads, and real trail rides reveal just how tough the AIR S truly is.

Stefan Imfeld, R&D Project Manager, opens the door to the next chapter – this is where we find out exactly how much adventure the AIR S can handle.

Vibration test – mechanical stability under fire

The vibration test shakes the maxon electric bike motor thoroughly to its core. A special vibration table simulates different surfaces such as gravel, concrete or forest floors with roots and drops. “The goal is to ensure that every screw, cable connection, and housing component reliably maintain their function over time,” says Stefan Imfeld.

The test is performed on all three axes to stress the BIKEDRIVE AIR S e-bike motor from every angle. Each side is exposed to the vibration profile for eight hours. This guarantees that nothing rattles, shakes, or loosens – no matter where the ride takes you.

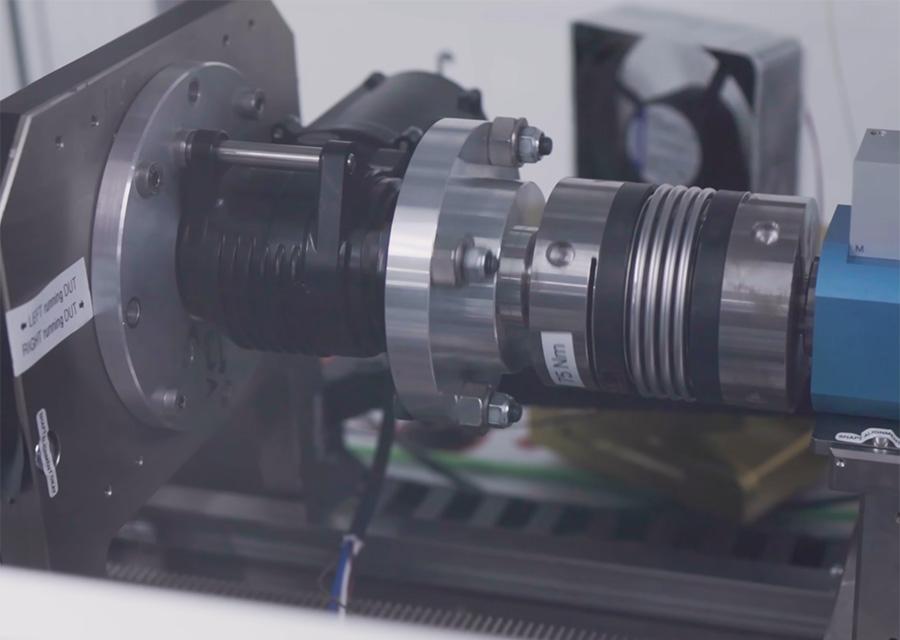

Load test – pushing the drive to its absolute limits

At this station the AIR S drive unit is measured across its entire cadence and torque range. The motor is actively operated under varying load conditions. “From these measurements we create an efficiency map that shows the drive’s efficiency across two dimensions,” explains Stefan Imfeld. This map reveals at which speeds and loads the e-bike drive operates most efficiently. Each motor is tested for the duration of a full battery charge.

In the same location, derating tests are carried out to check how the motor behaves under prolonged stress and how the motor intelligently reduces power to prevent overheating. At the same time, the freewheels are tested for long-term functionality by running through around 100,000 cycles – equivalent to about ten years of service life for an AIR S motor.

“The electric motors run 24/7. Depending on the test, measurements can take several days or even weeks,” says Stefan Imfeld. It’s an extreme endurance challenge that proves whether the AIR S can maintain its reliability under constant pressure.

Validation in real-world conditions

The maxon electric bike motor isn’t just tested in the lab – it also has to prove itself out on real trails. “For these field tests we rely on experienced internal and external test riders,” explains Stefan Imfeld. The groups are deliberately mixed: commuters provide data for typical everyday loads in urban environments, cross-country specialists generate load profiles on demanding trails, while uphill and downhill experts push the BIKEDRIVE AIR S system to its limits under extreme conditions.

Every ride delivers detailed data that our engineers analyze thoroughly. When potential optimizations are identified, improvements can often be implemented directly via firmware updates to further enhance performance.

On top of that, the e-bike motor undergoes intensive testing during training sessions with professional athletes from the Thömus maxon Cross-Country Team. Their feedback flows straight back into the development process and contributes to the further development of the drive system.

All tests passed – but how long does the power really last? In Part 3 we put the battery and range extender to the test. Stay tuned!