Does the BIKEDRIVE AIR S e-bike motor pass the toughest tests? – Part 1

Details

Behind every maxon e-bike drive lies precise engineering and hundreds of hours of intensive testing. Under conditions that mirror real-world use, we examine performance, durability, and reliability – without compromise.

The AIR S has to prove itself. And it does so under the same strict standards applied to all maxon products. “Only when it masters every challenge in the test lab is it ready for your adventure,” explains Stefan Imfeld, R&D Project Manager. “Robustness doesn’t happen by chance. We test every motor under extreme conditions – precisely because we reduced it to the essentials and reinforced the critical components,” adds Dominik Stockmann, Head of the Motors & Encoders Competence Center.

The drive unit isn’t tested just anywhere – it’s put through its paces in the very same lab where maxon products for medical technology, aerospace, and Formula 1 prove their reliability. Thanks to flexible test rigs, multiple tests run in parallel – there’s no fixed sequence. The majority of tests take place in-house at maxon. Only external influences such as dust, water, or electromagnetic compatibility are checked in specialized external facilities.

Discover the extreme tests a maxon e-bike motor has to endure. Stefan Imfeld takes us into the lab and shows us every station.

Acoustic chamber – engineered for silence

One of the standout quality features of maxon e-bike drives is their exceptionally low noise level. The BIKEDRIVE AIR S is virtually silent in operation. To guarantee this acoustic performance, measurements are taken in a sound-damped chamber.

“The e-bike is fixed on a bicycle simulator and controlled via the app to realistically simulate different riding scenarios,” explains Stefan Imfeld. A high-precision microphone records volume in decibels (dB) and detects even the smallest fluctuations. Background noise from the test equipment is measured separately and then subtracted from the final result.

Since even the tiniest ambient sound could distort the results, only one drive is tested at a time. The actual measurement takes just a few minutes but delivers critical data for noise optimization. The AIR S is among the quietest e-bike motors in its class and sets the benchmark for acoustic efficiency.

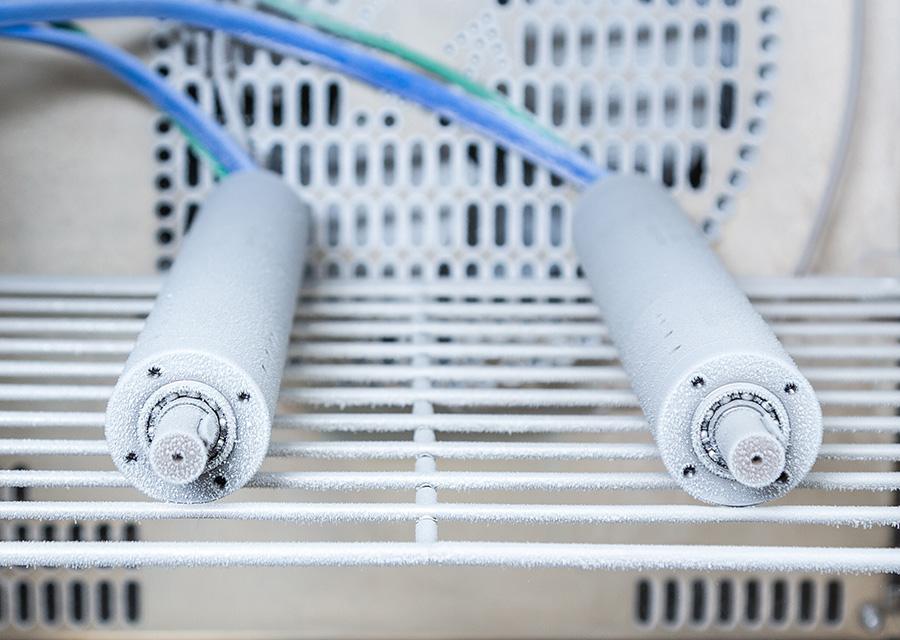

Climate test – surviving extreme temperatures

The climate test checks the temperature resistance of the maxon e-bike drive. It takes place inside a climate chamber where the ambient temperature can be controlled with precision. The cycle starts at room temperature, drops to –10 °C, rises to 50 °C, and returns to room temperature, where it is held for a defined period. This sequence is repeated ten times to realistically simulate the stress of changing temperature conditions.

The chamber replicates real-world scenarios such as winter mountain rides or sunbaked summer trails. This ensures the AIR S performs reliably even in extreme conditions. Several motors can be tested simultaneously in this phase, producing meaningful comparative data.

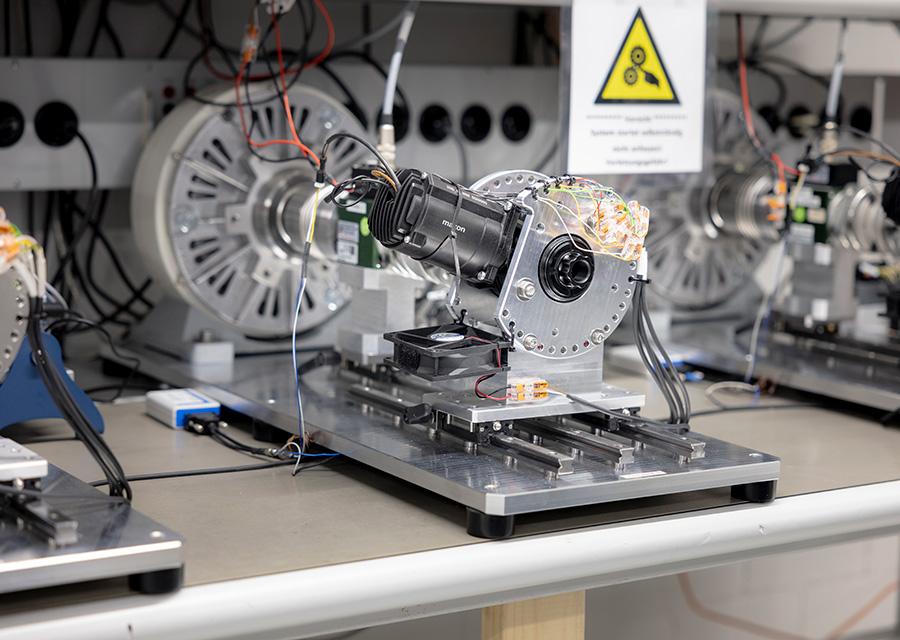

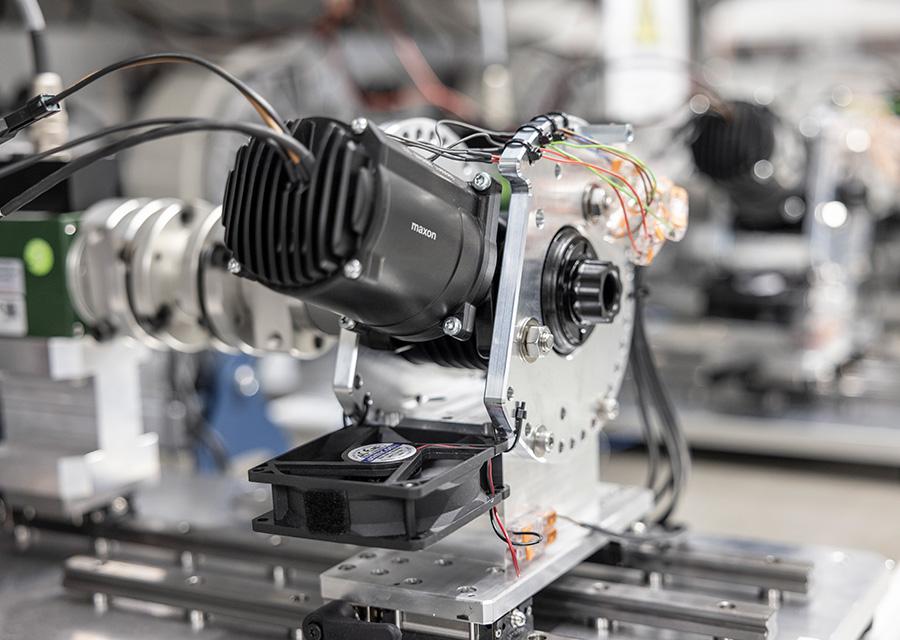

Endurance test – built for maximum reliability

The endurance test determines how long the mechanical drivetrain operates reliably. The goal for the BIKEDRIVE AIR S is a service life of at least 1,000 operating hours – equivalent to roughly 22,000 kilometers or about ten years of use.

Real rider data is analyzed and compiled into a generic riding profile.

“This allows us to simulate motor behavior as close to reality as possible,” says Stefan Imfeld. During the test, the electric e-bike motors run 24/7 with varying cadence and torque values. The profile starts at 10 RPM and ramps up continuously until every load scenario has been covered.

The BIKEDRIVE AIR S has cleared the first hurdles. But how does it perform when things really get tough? Stay tuned for Part 2: vibrations, load cycles, and real trails.