Efficient light e-bikes: What’s lost in weight is gained in fun

Details

When it comes to efficiency, the BIKEDRIVE AIR drive system from maxon sets new standards. But what does efficiency mean with regard to e-bikes?

High agility on technically challenging trails? Being able to carry an e-bike up a flight of stairs? Push it up a hill? Load it into a car? Disciplines where traditional e-bikes don’t excel. Motor and battery used to quickly make an e-bike weigh 20 to 30 kilograms. Lately, there has been a lot of movement in the industry – quite literally, as the maxon BIKEDRIVE AIR impressively demonstrates.

One of the lightest drive systems for light e-bikes

“Small, lightweight, and reliable electric motors form the DNA of our company,” says Thomas Steger. Coming from the bicycle industry, maxon’s product manager for e-bikes identified the market potential of lightweight e-bike motors several years ago. Thus the drive specialists from Switzerland, who otherwise build drives for Mars missions, industrial use, or surgical robots, proceeded to develop the maxon BIKEDRIVE AIR – one of the most efficient drive systems for e-bikes, and, clocking in at a system weight of 3.5 kilograms, a true lightweight.

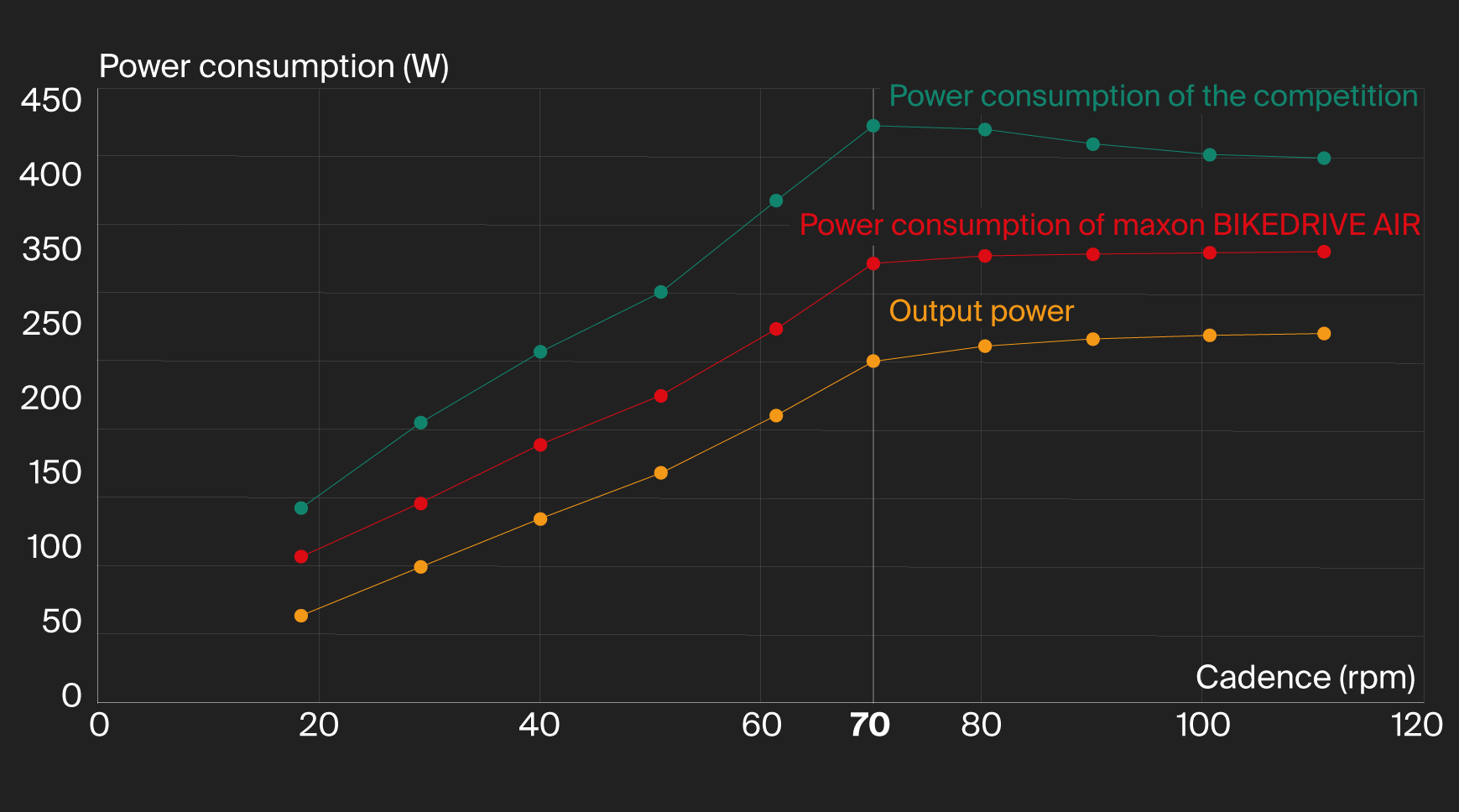

“At maxon, we define the efficiency of the drive system as the ratio between the motor power delivered to the chain ring and the power consumed from the battery,” explains Thomas Steger. “We see in tests that the maxon BIKEDRIVE AIR operates very efficiently – resulting in significantly lower power consumption from the battery for the same power output. This means it has a considerably higher range compared to competitors.”

Efficiency: Range is not only a matter of battery capacity

The focus is on how the drive can achieve the highest possible efficiency. Losses inherently occur as the power travels from the battery through the electronics and motor to the output of the gearhead. Or, to phrase it differently: The mechanical power output of an e-bike is lower than the electrical power consumed from the battery.

The resulting power losses are mainly converted into heat. This can cause the motor to decrease its output torque under heavy load, resulting in reduced assistance for the rider. “The maxon BIKEDRIVE AIR drive system has been designed using state-of-the-art simulation methods to minimize physical losses as much as possible. “Thus, we achieve the optimal combination of torque and range with the smallest amount of energy used,” says Steger.

Lab-tested: Taking a closer look at light e-bike motors

In the R&D and test laboratory in Switzerland, the maxon development team subjects the motors of various e-bike models to regular efficiency tests. “To measure the efficiency of the drive, we divide the mechanical output power by the electrical input power, at all possible operating points,” explains team leader René Waldvogel. “The latter is important since efficiency does not have a fixed magnitude.”

Tests conducted with competitor products reveal significant differences in power consumption. For example, to achieve an expected output power of 250 W at the chain ring, at 70 rpm, the maxon BIKEDRIVE AIR drive consumes approximately 321 W. The competitor product needs approximately 100 W more for the same result. That is lost power that becomes noticeable to the rider as reduced range.

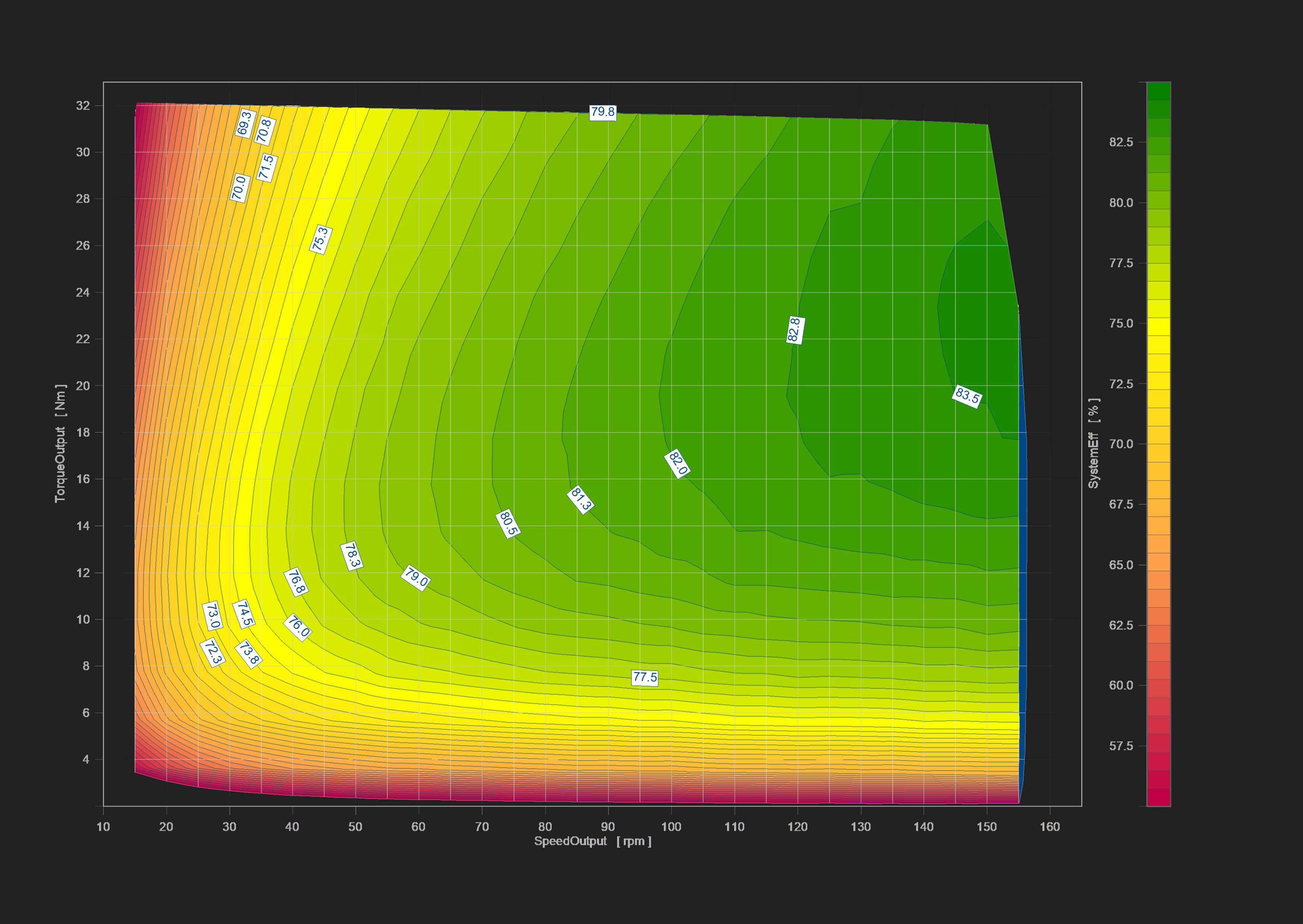

To illustrate technical efficiency, the developers create so-called efficiency maps. “We vary two influencing factors respectively while keeping the others as constant as possible,” explains René Waldvogel. The graphic below shows an example of such an efficiency map. In this case, it involves a drive at room temperature and constant input voltage, whereas the torque and speed have been varied.

Efficiency from the user’s perspective: Minimal weight, maximum power for a unique riding experience

The electric drives from maxon have proven to be the most efficient in these tests, i.e., they provided the highest range from the available battery capacity. But this technical approach does not tell the whole story – maxon also understands the efficiency of an e-bike from the end customer’s point of view. “Efficiency also means an optimal riding experience,” says product manager Thomas Steger, and continues to explain: “To achieve this, we have identified the perfect balance between power, weight, and functionality. With the maxon BIKEDRIVE AIR, frames can return to their traditional and familiar geometry. For frame designers and bike manufacturers, there are virtually no limitations or restrictions.”

The high versatility is an important factor: “A lightweight e-bike is particularly appealing to sporty riders who wish to ride only a portion of the route with electric assistance and complete the rest using their own muscle power, with the battery turned off.” And these riders are grateful for every kilogram saved, especially on demanding routes. With the maxon BIKEDRIVE AIR, they get maximum performance from their e-bike motor with a minimum of weight. And they thus make optimal use of the available energy – both their own and that of their battery.